FY-800 Fully Automatic Slag Discharge Centrifugal Filter

Centrifugal oil purifier: pure in rotation, protecting the quality

of every drop of oil for you!

- Centrifugal oil purifier, with its unique rotating technology,

easily separates impurities in the oil, and keep your equipment

always maintain the best condition.

- No need to frequently replace the filter screen, filter element,

centrifugal oil purifier can save a lot of costs for you. Simple

operation, you can enjoy a long-term stable cleaning effect, and

keep your oil always remain clear and transparent.

- Using physical separation technology, without adding chemical

agents, centrifugal oil purifier is not only efficient and

energy-saving, but also a model of environmental protection. Let us

protect the earth together.

- The centrifugal oil purifier has a cleanliness of more than 95%,

providing the purest power source for your equipment, making your

production smoother and more efficient.

| Technical parameters |

| Device name | Fully automatic slag removal centrifugal oil purifier |

| Project/Model | FY800 |

| Filter method | centrifugation |

| Slag discharge method | Automatic slag discharge |

| drum capacity | 8L |

| Maximum throughput | 100L/min |

| Recommended traffic | 50-80L/min |

| Speed | 3200r/min |

| Centrifugal effect G | 1700G |

| main motor | 2.2kw2P.380V |

| Auxiliary motor | 0.09kw4P.380V |

| total power | 2.29kw |

| Import pipe diameter | DN25 |

| Outlet diameter | DN65 |

| Air pressure range | 0.4-0.6 MPa |

| Start mode | Inverter starts |

| control Panel | touch panel |

| Control method | automatic/manual |

| Equipment size | 870*860*1550 (mm) |

| working temperature | 0~80℃℃ |

| Storage temperature | -20-80℃℃ |

| weight | 388kg |

Scope Of Application

- Online and post-processing of cold forming oil

- Centralized recovery of thread tapping oil

- Solid-liquid separation of cutting oil in mechanical processing

- Filtration of drawing oil for aluminum cable

- Powder metallurgy finishing oil and grinding oil, etc.

- Steel pipe drawing oil

Working Principle

1. Oil/industrial liquid is delivered to the equipment through the

oil pump. When the oil/industrial liquid and impurity particles

enter the separation rotor, they are subjected to strong

centrifugal force (up to 2000 times the weight of the impurities).

The oil/industrial liquid and impurities move radially to the inner

surface of the rotor. The oil/industrial liquid and the impurities

therein are compressed into a thick layer. Due to the different

centrifugal forces, the oil/industrial liquid flows back to the

transfer tank along the reflux tank. The impurities are adsorbed to

the inner surface of the separator and gradually solidified,

achieving the effect of separating impurities from oil/industrial

liquid, so that the cleanliness of oil/industrial liquid is

continuously improved!

2. Difference from traditional filtering methods: Traditional

(interception) filters intercept impurities through filter media,

and their filtering accuracy is guaranteed by the filter media

used. When the filter media load is too large, that is, the

pressure difference at both ends is too large, there may be a risk

of the filter media being torn (punctured), and the cost of

replacing the filter element is high.

Advantages

1. It can automatically separate the sludge in the oil and

automatically remove and discharge the sludge, without manual

cleaning and consumables.

2. The frequency conversion design can freely adjust the speed to

change the centrifugal force G value.

3. The control panel is a full touch LCD panel, which adopts PLC

program design. The filtering time, automatic slag removal time and

other settings can be set by yourself.

4. It can quickly separate impurities in oil or water and

automatically discharge slag.

5. Separate impurities above 0.45-3μm in oil (phosphoric acid

powder, oil sludge and iron powder, etc.).

6. It can realize fixed or mobile filtration to maximize the

effectiveness of the equipment.

7. Fully automatic control, automatic slag removal, saving labor.

8. The scraped sludge has a low oil content and can be directly

discarded without de-oiling.

9. There is no replacement of filter screens and filter cores, and

no consumables.

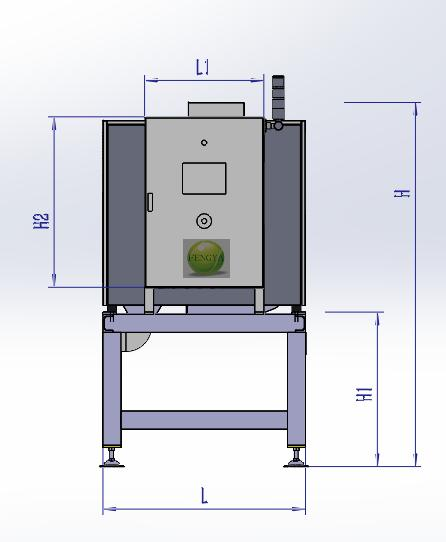

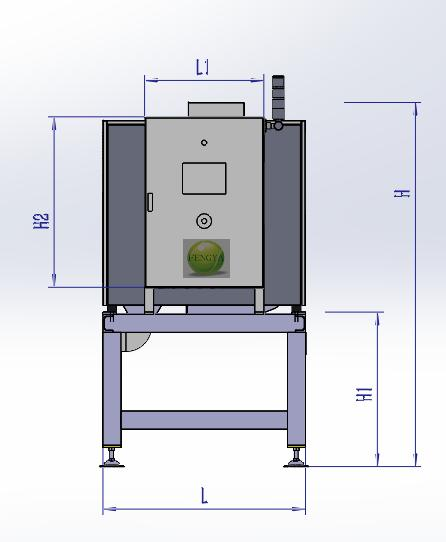

| Model | L | L1 | W | W1 | W2 | W3 | H | H1 | H2 |

| FY-600 | 770mm | 430mm | 940mm | 720mm | 565mm | 220mm | 1560mm | 690mm | 660mm |

| FY-800 | 970mm | 530mm | 1050mm | 810mm | 600mm | 220mm | 1620mm | 875mm | 760mm |